The Essential Guide to Warehouse Risk Reduction

Discover the most common hazards found in warehouses and the practical steps you can take to protect your people, equipment, and operations.

Why Warehouse Safety Needs To Be A Top Priority

Loading Bays & Delivery Areas

Explore All Loading Bay Protection

Racking & Storage Zones Key Risks

Explore Rack Protection Solutions

Pittman Guardz U-Shaped Pallet Racking Upright Protector

Sale price€41.50ex VAT

Pittman Guardz 90° Pallet Racking Upright Protector

Sale price€37.50ex VAT

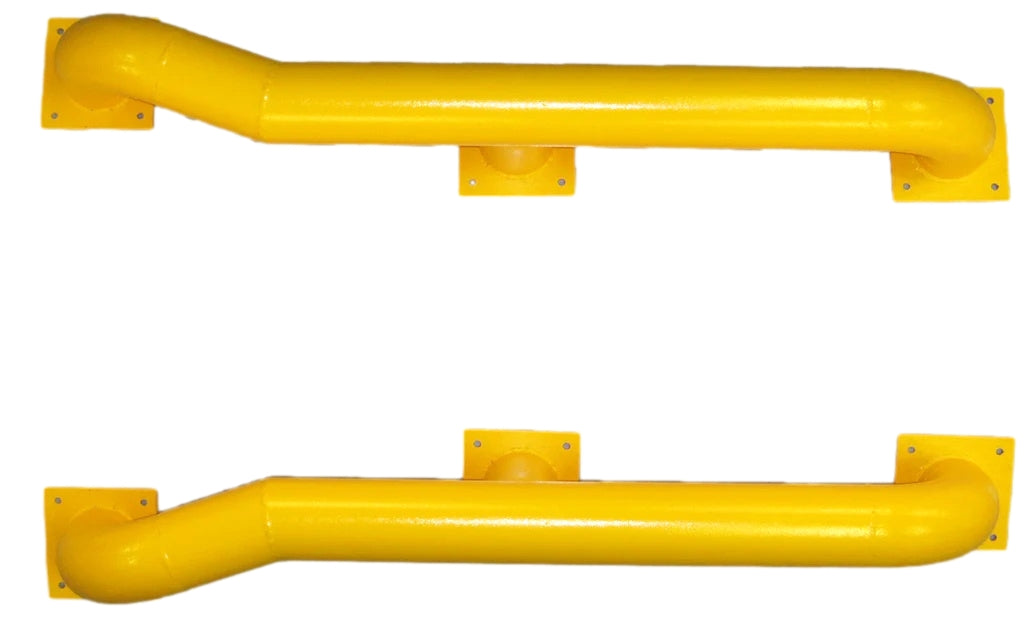

Pittman Guardz Pallet Rack End Protectors

Sale priceFrom €148.00ex VAT

Pittman Guardz Warehouse Bollards

Sale priceFrom €52.00ex VAT

Pedestrian Walkways & Staff Areas

Explore Warehouse Safety Solutions

Pittman Guardz Sub Surface Loading Bay Bollard

Sale price€410.50ex VAT

Pittman Guardz U-Shaped Pallet Racking Upright Protector

Sale price€41.50ex VAT

Pittman Guardz 90° Pallet Racking Upright Protector

Sale price€37.50ex VAT

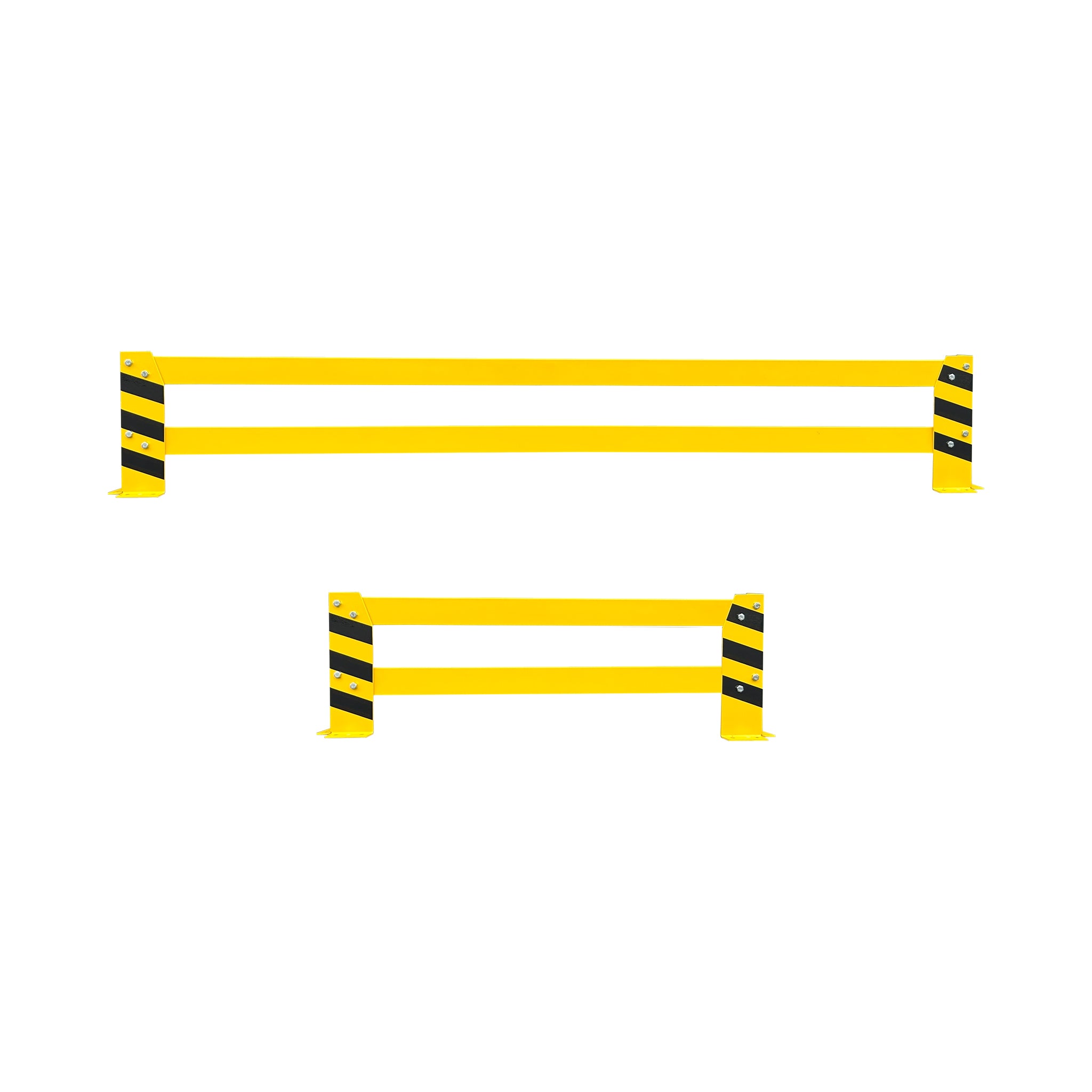

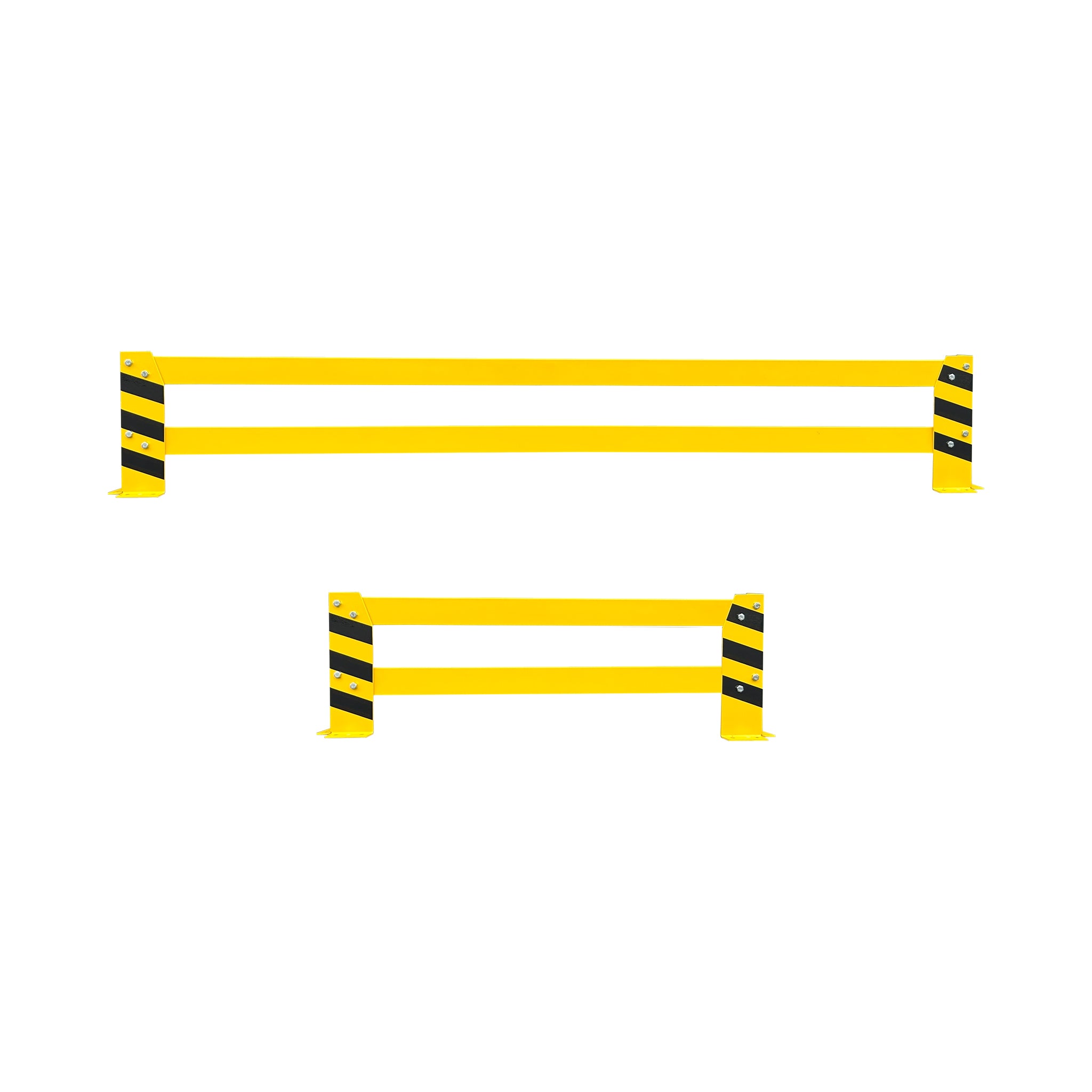

Pittman Guardz Pallet Rack End Protectors

Sale priceFrom €148.00ex VAT

Machinery & Critical Infrastructure

Explore Impact Protection Solutions

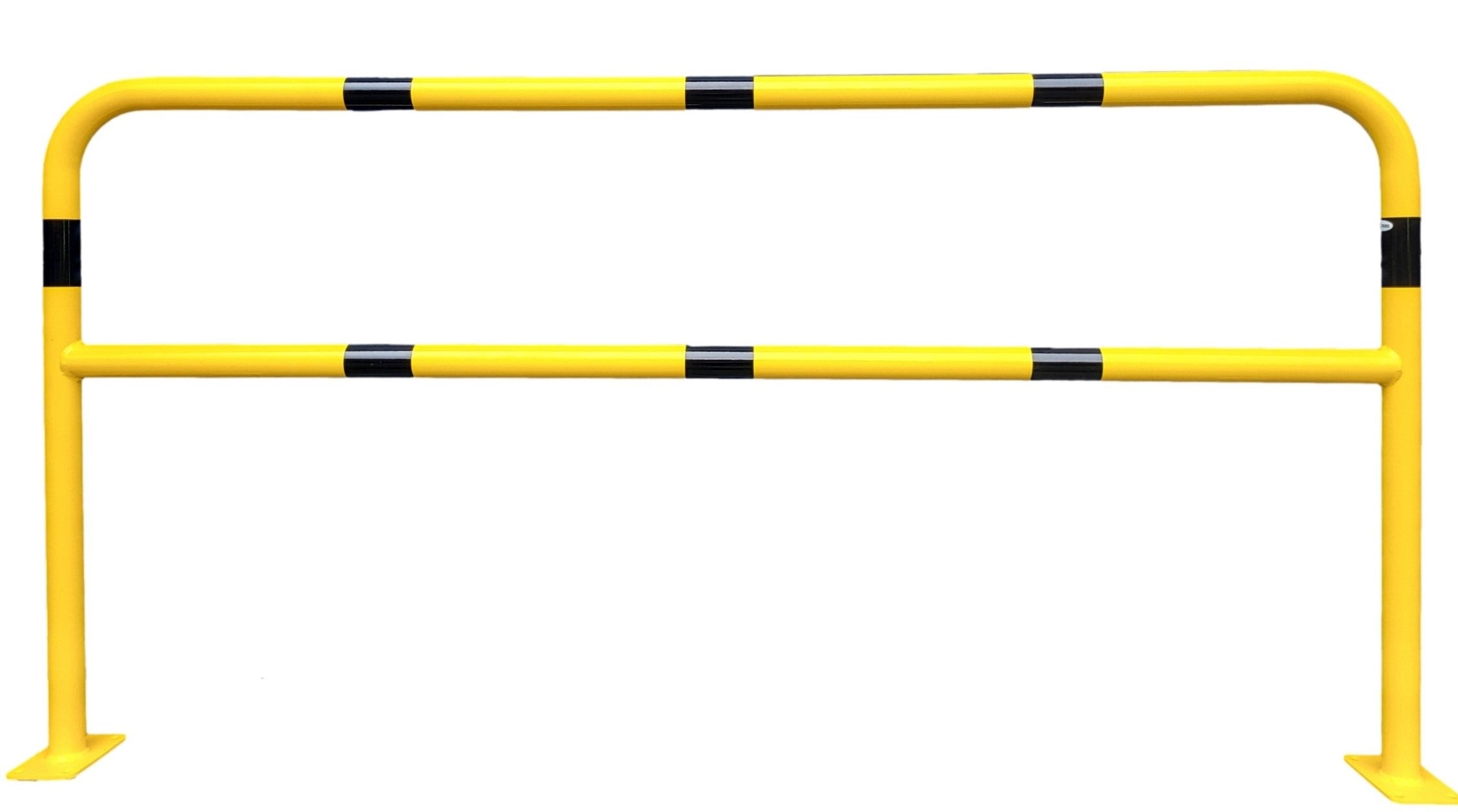

Defender Warehouse Hoop Barrier - 1000mm Wide

Sale priceFrom €229.00ex VAT

Hot-Dip Galvanised and Powder-Coated

Defender Warehouse Hoop Barrier - 1500mm Wide

Sale priceFrom €299.00ex VAT

Hot-Dip Galvanised and Powder-Coated

Defender Warehouse Hoop Barrier - 2000mm Wide

Sale priceFrom €239.40

Regular price€399.00ex VAT

Hot-Dip Galvanised and Powder Coated

Defender 90 Degree Steel Corner Protector

Sale priceFrom €356.00ex VAT

Tough Corner Defense for Long-Lasting Safety

Spill Control & Impact Protection

Explore Spill Control Solutions

SpillChamp 15 Litre Chemical Spill Kit

Sale price€32.88ex VAT

Convenient Kit for Small Acid & Chemical Spills

SpillChamp 15 Litre Maintenance Spill Kit

Sale price€30.38ex VAT

Convenient Kit for Small Workplace Spills

SpillChamp 15 Litre Oil and Fuel Spill Kit

Sale price€30.38ex VAT

Convenient Kit for Small Oil & Fuel Spills

SpillChamp 50 Litre Maintenance Spill Kit

Sale price€149.73ex VAT

Convenient Kit for Small to Medium Workplace Spills