Loading Bay Wheel Guides

A range of all-steel Wheel Guides for safe and reliable truck parking in warehouses and loading bays. Aid truck parking and protect loading bay assets.

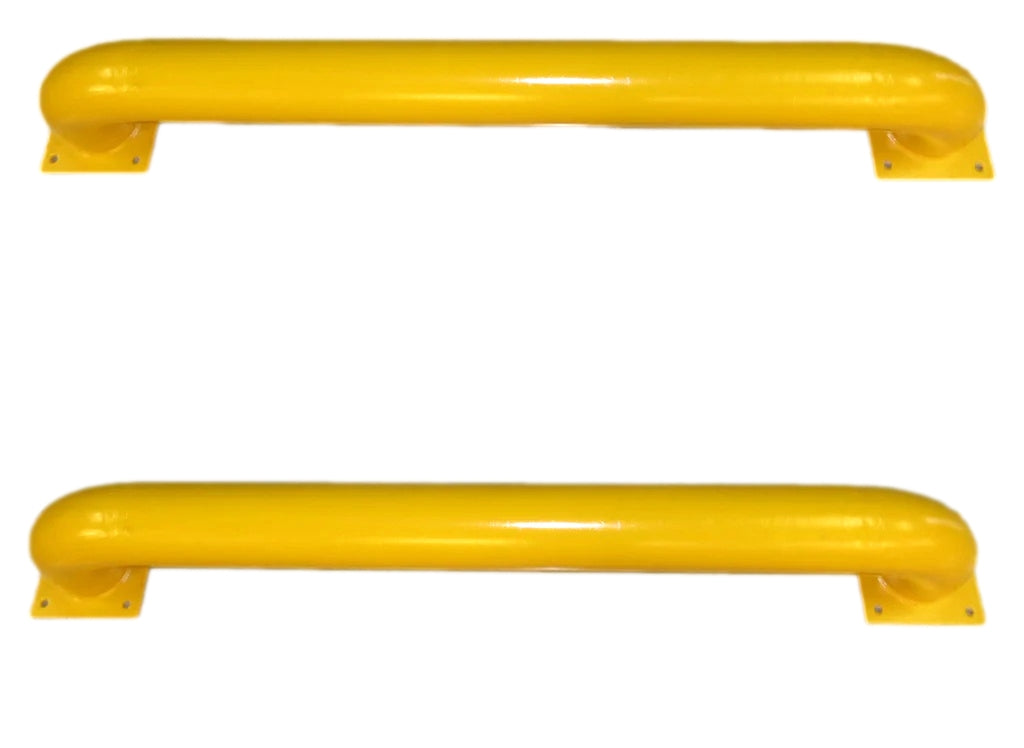

Low Profile Wheel Guides Pair

Sale price€1,056.00ex VAT

Suitable For Lower Profile Vehicles Or Trailers

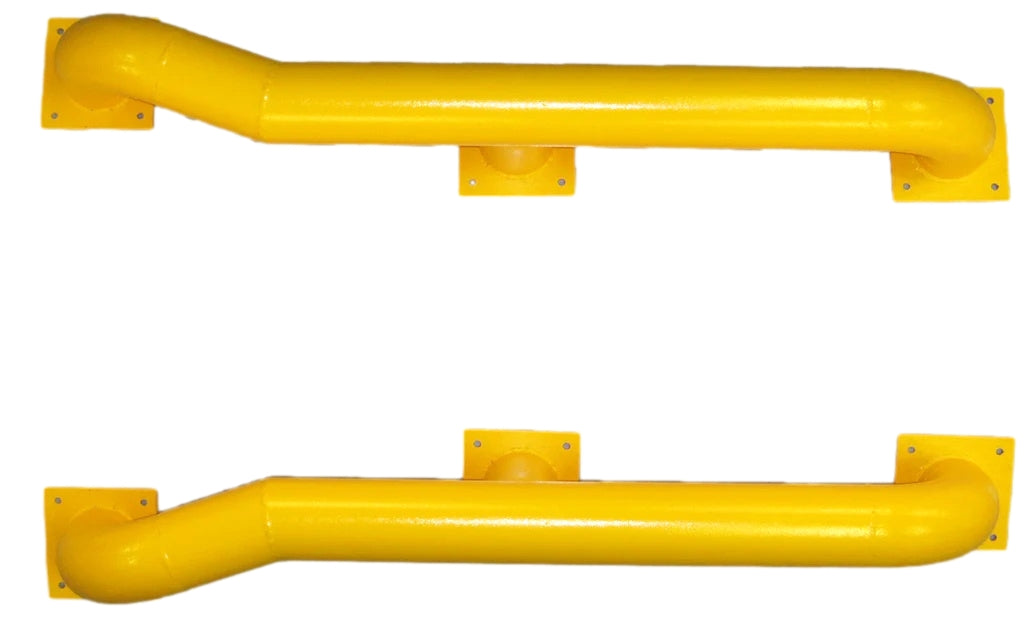

Black Bull Cranked Wheel Guide

Sale priceFrom €1,593.00ex VAT

Reduces Incidence Of Damage To Loading Bays

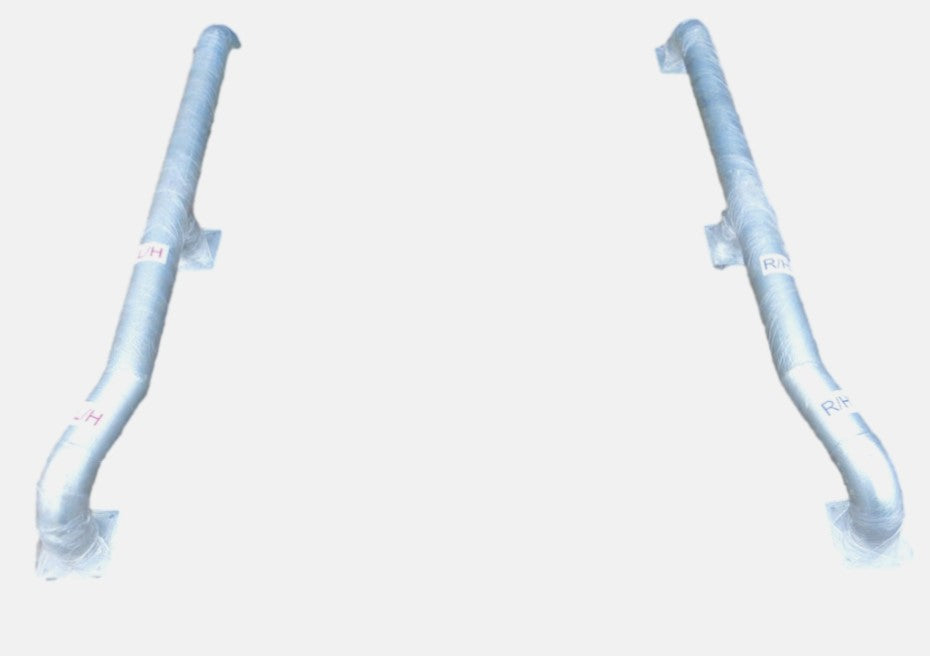

Economy Steel Wheel Stops - 2500mm x 170mm

Sale price€952.00ex VAT

Coach Wheel Stop

Sale price€145.74ex VAT