Wheel Stops

A wide range of rubber and steel Wheel Stops for cars, vans and trucks. Durable and cost-effective asset protection for car parks, warehouses, and loading bays.

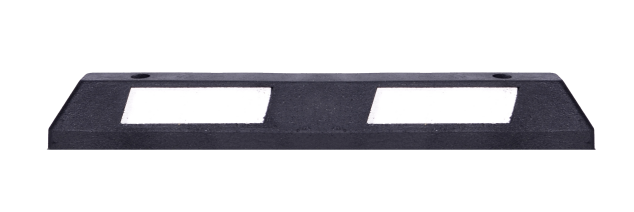

Eco-Park Wheel Stop

Sale priceFrom €49.50

Regular price€3,960.00ex VAT

Tough, Eco-Friendly & Built To Last

Park It 1800mm Rubber Wheel Stop (Yellow)

Sale price€69.50ex VAT

Reduce Vehicle Impacts in Car Parks

Park It 1200mm Rubber Wheel Stop (Yellow)

Sale price€69.50ex VAT

100% Recyled Rubber with Zero Maintenance

Park It 900mm Rubber Wheel Stop (Yellow)

Sale price€54.00ex VAT

100% Recycled Rubber with Zero Maintenance

Coach Wheel Stop

Sale price€145.74ex VAT

HGV Dock Wheel Stop

Sale price€334.63ex VAT

XPT - Rubber Traffic Lane Separators

Sale price€100.00ex VAT

Economy Steel Wheel Stops - 2500mm x 170mm

Sale price€952.00ex VAT

XPT Rubber Curb

Sale priceFrom €89.50ex VAT

Parker 1000 Lane Seperator

Sale price€34.95ex VAT

UV Stabilised PVC - Excellent Alternative to Concrete

Traffic Lane Wheel Stop with Flexi Post

Sale price€75.32ex VAT

Park It 1800mm Rubber Parking Curb (Blue)

Sale price€99.50ex VAT

Reduces Vehicle Collisions At EV Chargers

Park It 1800mm Rubber Wheel Stops (White)

Sale price€69.50ex VAT

Reduce Car Collisions in Parking Bays