Workplace Spill Management: A Complete Guide to Spill Kits and Spill Control

Spills happen. Whether it’s water, oil, or something more dangerous like chemicals or acids, they’re a common challenge in workplaces where liquids are handled daily. While general spills are usually manageable, hazardous spills can become serious risks without proper management. That’s why spill kits are a must-have for workplace safety.

In this guide, we’ll break down why spill kits are essential, how to choose the right one, and share practical tips for handling spills effectively.

Why Spill Kits Are Essential for Workplace Safety

From a leaky oil drum to a chemical splash or an unexpected maintenance mess, workplace spills come in all forms. Without the right tools, cleanup can be messy, time-consuming, and even dangerous.

Spill kits are pre-packed solutions tailored to specific types of spills, ensuring quick and efficient cleanup. They protect employees, reduce downtime, and keep operations running smoothly—whether for emergencies or as a preventive safety measure.

Types of Spill Kits: Choosing the Right One for Your Spill

Spill kits aren’t one-size-fits-all. The right kit depends on the type of liquids in your workplace and the potential spill risks. Here the most common types of spill kits and what they can be used for.

Oil and Fuel Spill Kits

These kits are ideal for workplaces handling oils and fuels, such as garages, warehouses, and freight depots. They contain specialised pads, socks, and cushions that absorb oil while repelling water, maximising efficiency.

- Suitable for: Oil, fuel, hydrocarbons, and other oil-based liquids.

- Used in: Garages, workshops, manufacturing, and vehicles for emergency response.

- Example: A forklift leaks hydraulic oil in your warehouse. An oil spill kit allows quick containment and cleanup without absorbing water.

Chemical Spill Kits

Chemical spills can be highly dangerous, potentially causing fires or releasing toxic fumes. These kits are tailored for handling aggressive substances like acids and alkalis.

- Suitable for: Acids, alkalis, chemicals, and corrosive materials.

- Used in: Labs, storage facilities, and pharmaceutical manufacturing.

- Example: A container of cleaning solution tips over in storage. A chemical spill kit ensures safe cleanup while protecting staff from exposure with PPE.

Maintenance Spill Kits

For general-purpose spills like water, coolants, or non-hazardous liquids, maintenance spill kits are versatile and reliable.

- Suitable for: Water-based liquids, coolants, and general leaks.

- Used in: Factories, warehouses, and workshops.

- Example: A machine leaks coolant onto the factory floor. A maintenance spill kit quickly absorbs the spill, minimising downtime.

Spill Kit Containers: Choosing the Right Storage

Most spill kits come in a handy container to easily store all the kit components. From bags and boxes to wheelie bins, spill kit containers allow them to be mobile or storable when needed.

The size of the container can also determine the absorbency of the overall kit—the larger the container, the more spill-control products you can store. Here’s a quick breakdown:

- Bags: Lightweight and portable, ideal for mobile workers or vehicles. Absorbency: 10–30 litres.

- Boxes: Compact and storable, perfect for moderate spills. Absorbency: 40–80 litres.

- Static Bins: Durable, high-capacity containers for fixed locations. Absorbency: 200–500 litres.

- Wheelie Bins: Mobile, heavy-duty bins for quick spill responses. Absorbency: 120–1200 litres.

What’s Inside a Spill Kit?

The contents of a spill kit can vary from brand to brand. However, most kits contain the essential components to absorb, protect against, and clean up the spill. But what's inside a typical spill kit?

- Spill Pads: applied directly to spills for quick initial soakage. Most pads will soak up to 1 litre of liquid each, allowing for easy disposal once used.

- Spill Cushions: ideal for tight spaces where the pads cannot reach. They are perfect for absorbing spills under machinery or valves and absorb 2-3 litres each

- Spill Socks: tube-shaped spill absorbers that help isolate the spill. They can be placed around the spill, creating a “barrier” and preventing it from spreading to stock or assets.

- PPE: Goggles and gloves to protect cleanup staff.

- Barrier tape: a highly noticeable tape that warns pedestrians to stay away from the area

- Waste Bags: Heavy-duty bags for safe disposal of used materials.

Optional add-ons:

These items are not in most kits, but can be a handy optional extra if you want more comprehensive spill control in your workplace.

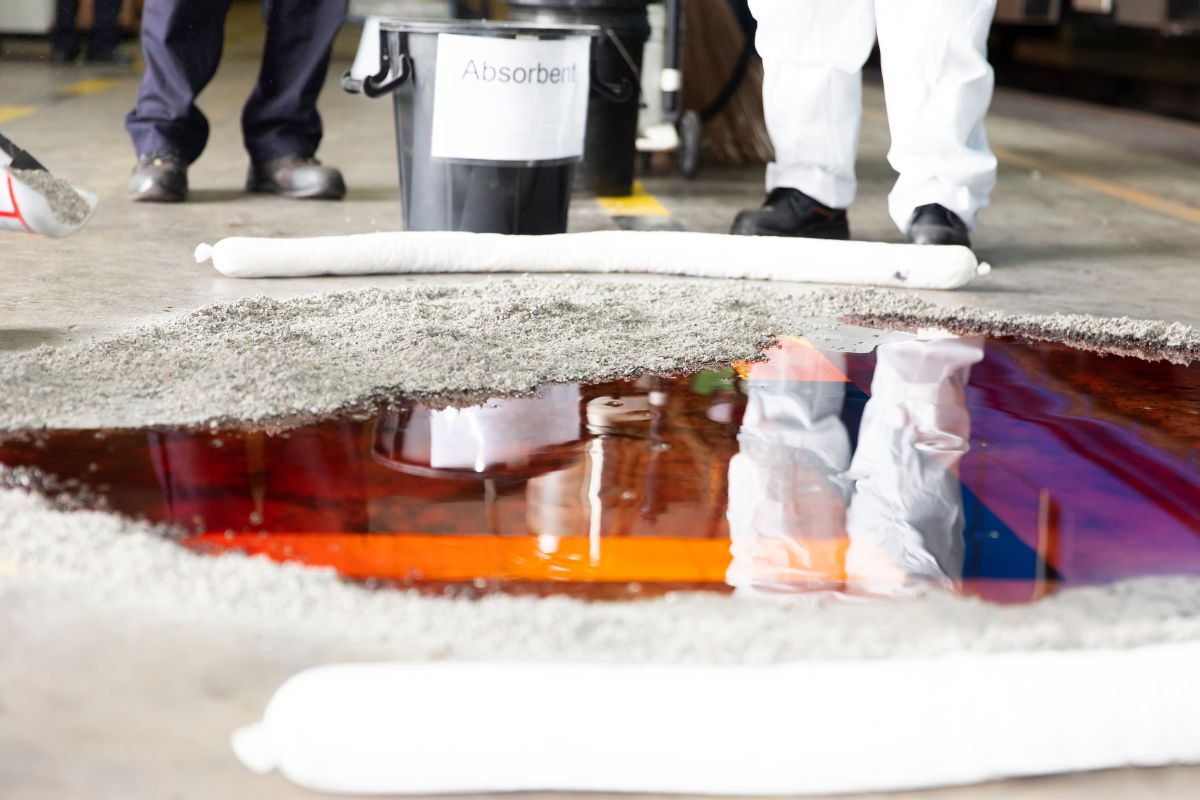

- Absorbent granules: not contained in every spill kit, but some will contain granules that can be applied directly to spill for soakage. Once spills are absorbed, they are easily swept or disposed of.

- Drain covers: usually made from clay or polyurethane, drain covers prevent dangerous spills from flowing into open drains.

- Putty or sealant: easily applied directly to cracks or holes in containers for a temporary fixing solution

A Guide to Handling Spills in the Workplace

Dealing with a spill can be a daunting task, but by remaining calm and following specific steps you can isolate and clean the spill before it causes any major issues.

Assess the Spill - when a spill happens, the first step is to assess it. What’s been spilled? How much? What’s at risk? Knowing these details is crucial. If you’re unsure, check the container label or safety data sheets for guidance. This information helps you plan the safest and most effective cleanup process.

Apply PPE - personal protective equipment (PPE) is non-negotiable for anyone handling a spill. At a minimum, wear gloves and goggles before approaching. For more hazardous materials, additional PPE might be required—again, safety data sheets can guide you.

Isolate the Spill - containment is key. Use spill socks from your spill kit to block or divert the spill, keeping it away from stock or sensitive areas. Aim to create a barrier as far from the spill as possible to prevent it from spreading, especially into water sources.

Identify the Source - locate and stop the source of the spill. It might be as simple as righting an overturned barrel or plugging a leaking container. Addressing the source quickly prevents further spillage.

Start the Cleanup - once the spill is contained and the flow has stopped, start the cleanup. Use the appropriate supplies for the material involved. Remember, any used cleanup materials are considered hazardous waste and must be disposed of properly. Also, remove and replace any damaged or leaking containers.

Deep Clean and Disposal- thoroughly decontaminate the area. If the spill occurred outside, remove contaminated soil or gravel, especially with hazardous substances. Dispose of used PPE that came into contact with the spill and clean the area completely before allowing others to re-enter.

Analyse and Report - finally, document the incident. Determine the cause of the spill and identify steps to prevent future spills. Update and restock spill kits as needed, and re-train staff if required. Being prepared and learning from incidents minimises risks moving forward.

Tips for Effective Spill Response

Managing spills effectively comes down to being prepared and acting fast. With the right tools and clear procedures, your team can handle spills safely and minimise risks. These tips will help you build a practical, effective spill response plan, no matter the size of the spill.

Strategic Placement: Keep kits near high-risk areas like chemical storage, machinery, or loading bays. Easy access to spill kits means fast response times.

Training: Ensure all employees know how to use spill kits safely and effectively. Trained employees are safe employees when it comes to spill response.

Regular Checks: Periodically inspect kits and replace used items. Most kit containers are fully reusable and only need to be restocked.

Access Control: Use barriers to block off the spill area, keeping employees safe. Portable barriers can be moved around as needed and help you block off spills in a hurry.

Final Thoughts

Preparation is key when it comes to spill control. Spill kits are an inexpensive investment that pay off big in workplace safety and can help workplace staff prepare for the worst. By understanding your needs and choosing the right kit, you’ll be prepared to handle spills quickly and efficiently. Training staff to use spill kits can be a priceless boost to the workplace, the environment, and themselves.